Super Core

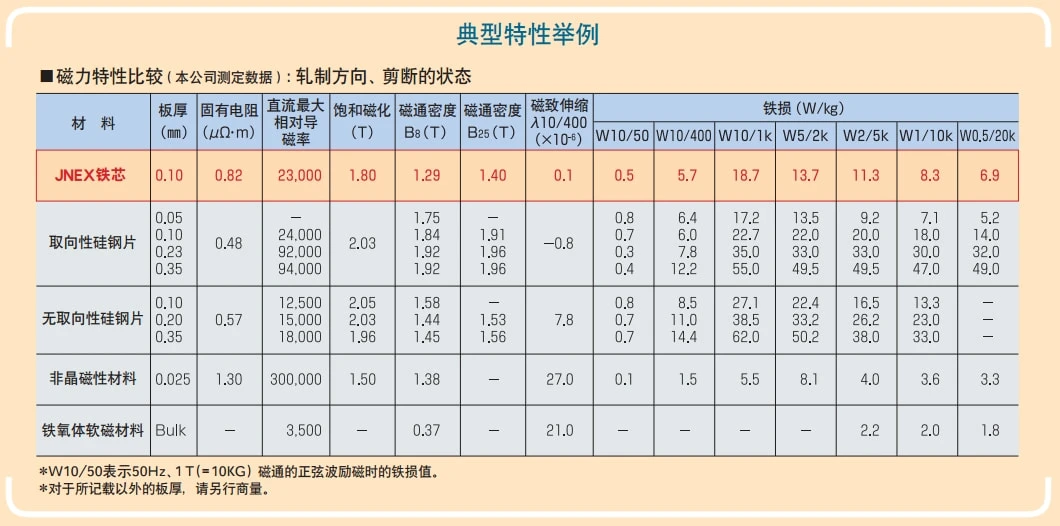

Super Core is manufactured using an innovative process that is completely different from that for conventional silicon steel sheets. These are the highest grade, non-oriented magnetic steel sheets available.

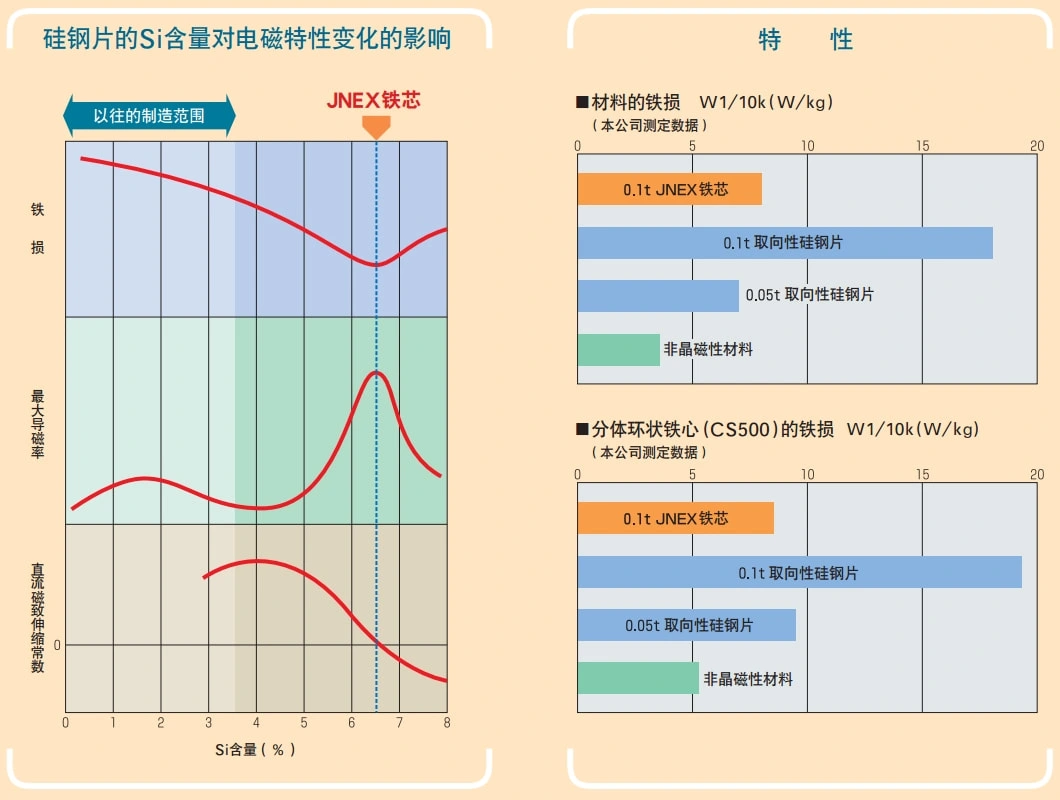

Conventional silicon steel sheets have a Si (silicon) content of 3.5% or less. It has long been known that the magnetic characteristics of a silicon steel sheet improve as the Si content increases, peaking at 6.5%.

However, it has been impractical to produce thin steel sheets with a Si content of over 3.5% because the steel tends to harden and become brittle. In 1993 JFE Steel solved this production problem through the adoption of a process called the CVD process, and successfully introduced the first 6.5% Si steel sheets (JNEX-Core) to the world. In order to meet new demands, this technology has continued to be developed, leading to the commercial production of gradient high-silicon steel sheets with superior high-frequency characteristics (JNHF-Core).

JNEX-Core /10JNEX900

JNEX-Core is the highest-grade non-oriented magnetic steel sheets manufactured with a production method (CVD process) that is completely different from that for conventional silicon steel sheets, allowing a previously impossible Si content of 6.5%.

|

Low Core Loss |

Core loss in high-frequency ranges is extremely low. This allows for low heat generation and size reductions for magnetic components such as high-frequency reactors and transformers. |

|---|---|

|

Low Magnetostriction |

Magnetostriction which causes noise and vibration is nearly zero. This enables significant noise reductions for magnetic components such as reactors and transformers. |

|

High Permeability |

The permeability is extremely high across a wide range of frequencies, making it highly suitable for use in shield applications and CT. |

|

Stable Quality |

The high-temperature processing provides thermal stability. Since there is minimal deterioration of the properties due to machining, so stress-relieving anneals are not required. |

|

Non-oriented |

There is virtually no difference in the characteristics between the rolling direction (Ldirection) and the transverse (C-direction). Therefore, this can be used in a wide range of applications, from stationary machines to rolling machines. |

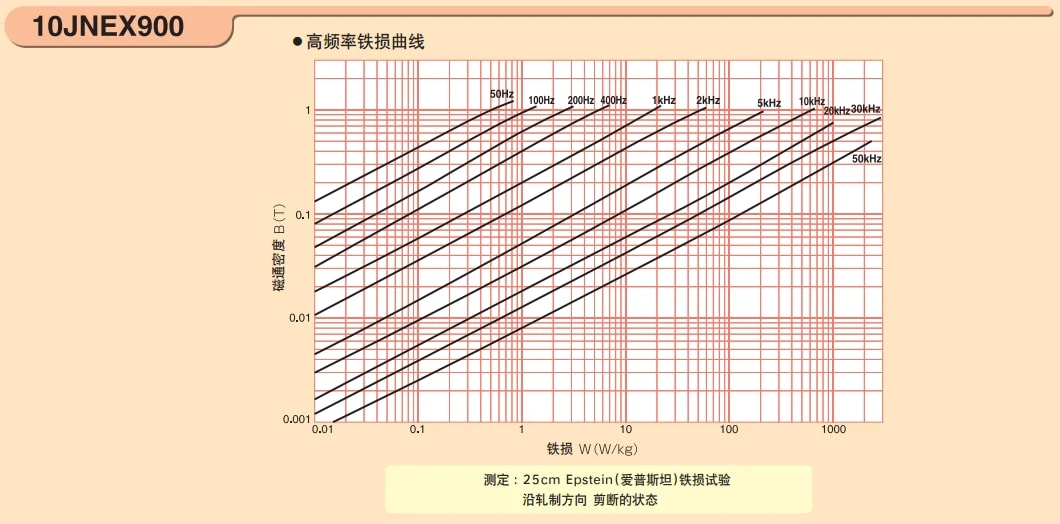

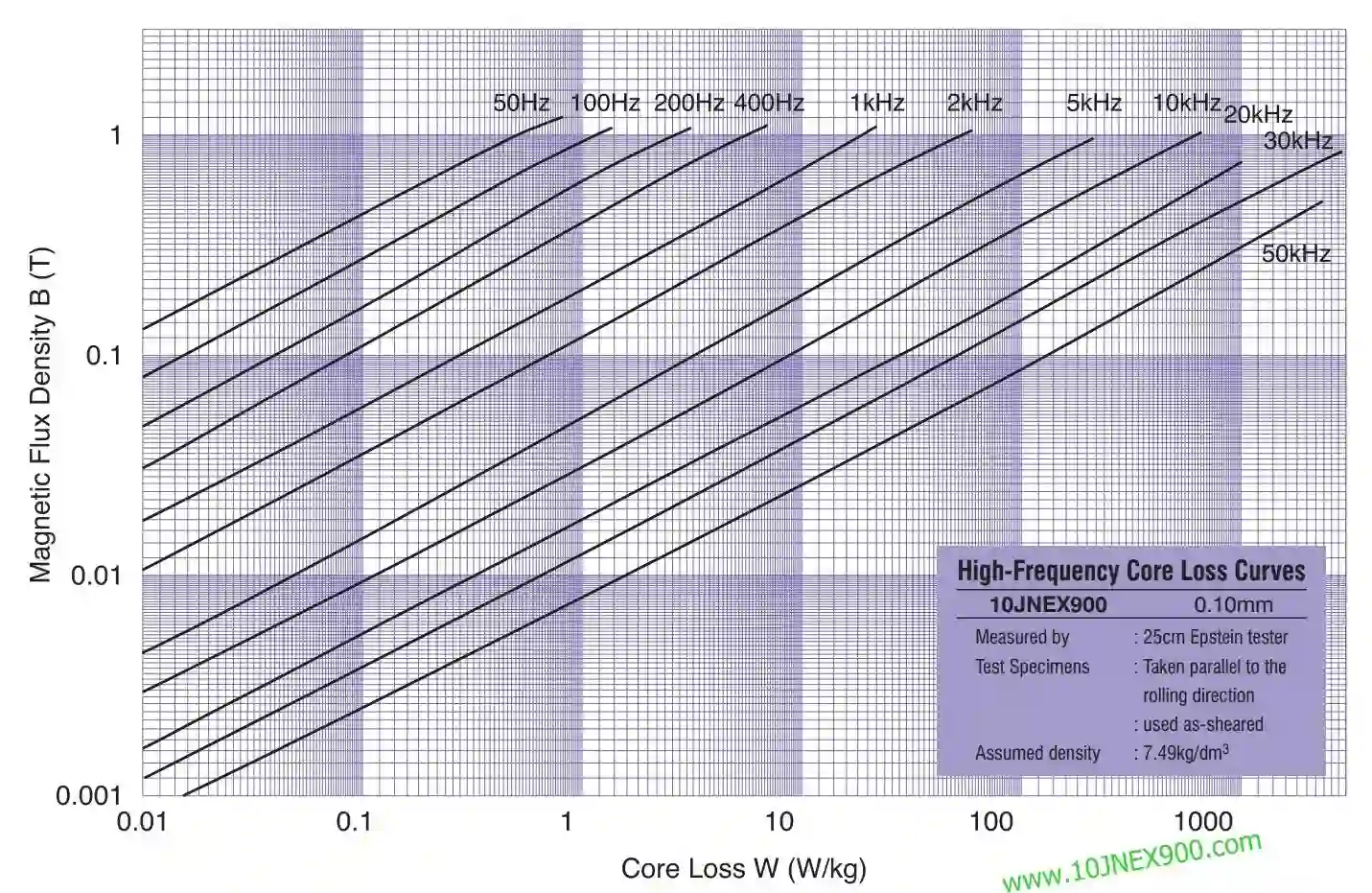

10JNEX900 High-Frequency Core Loss Curves

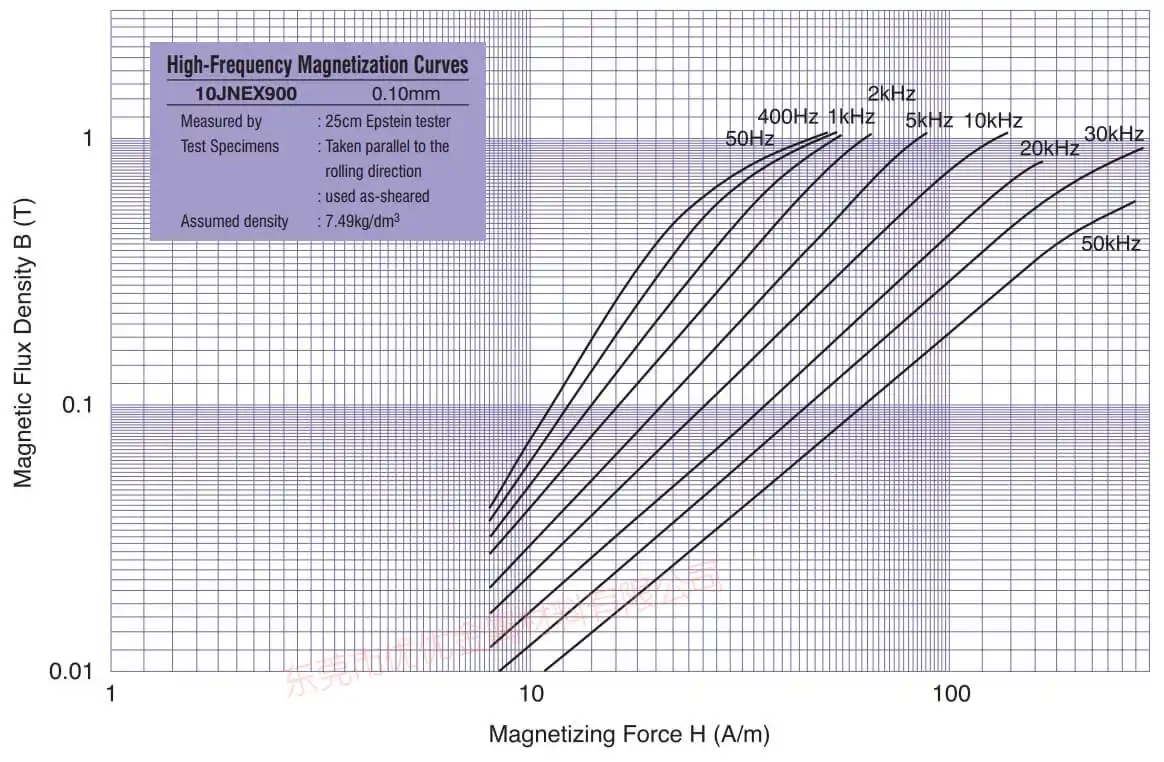

10JNEX900 High-Frequency Magnetization Curves

JNHF-Core /10JNHF600

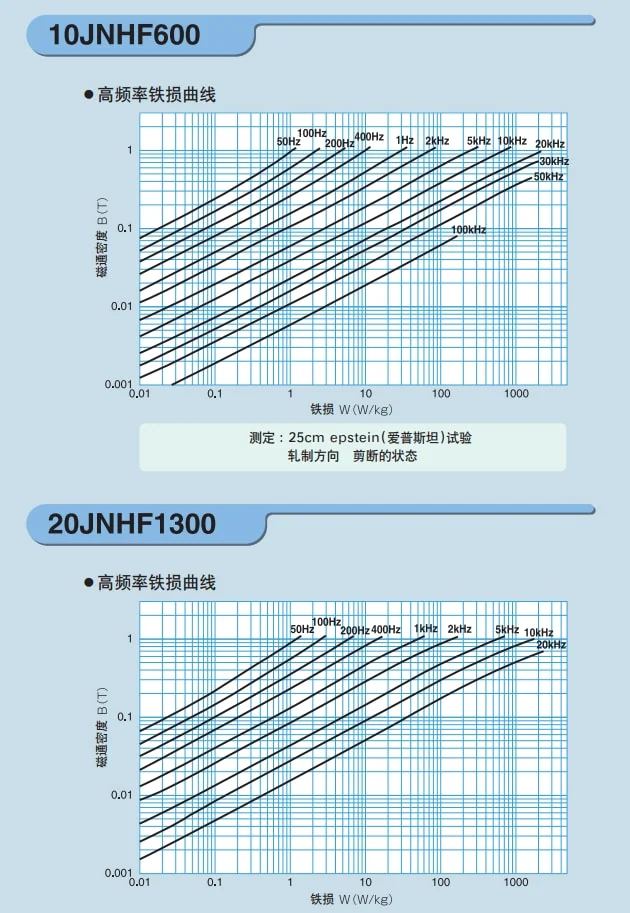

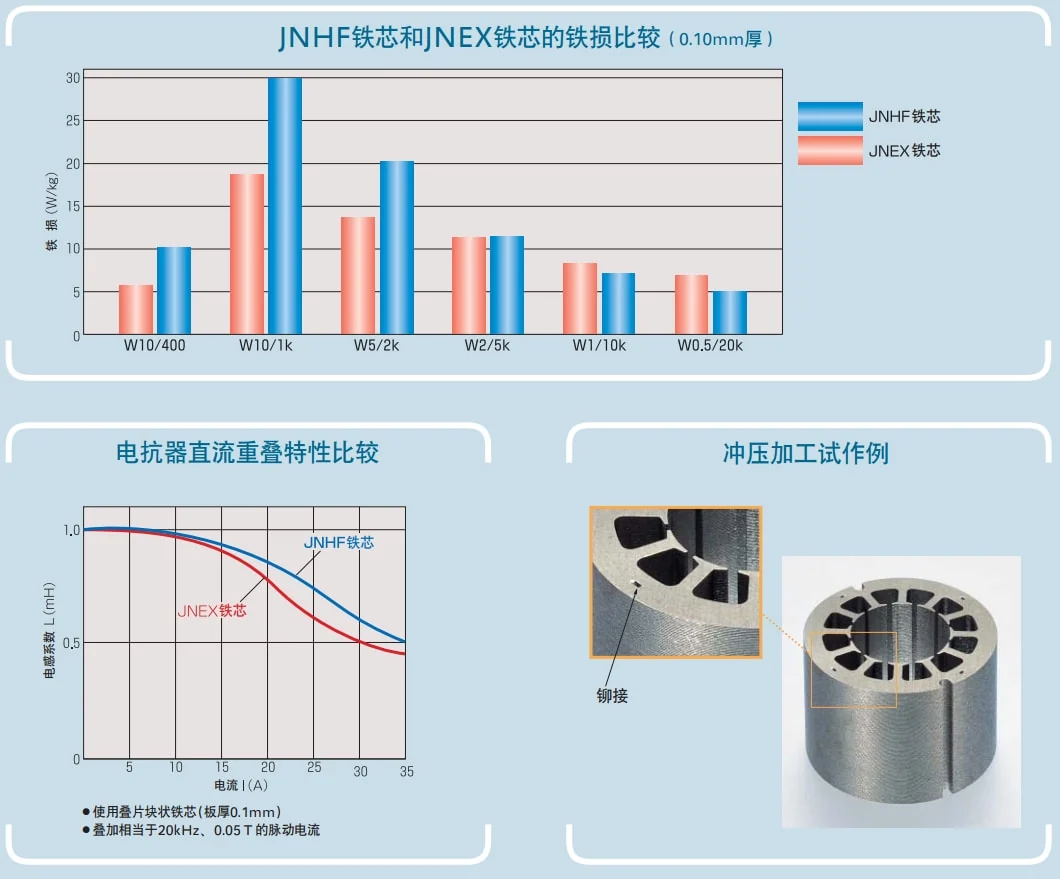

For the JNHF-Core, the siliconization technology (CVD process) used for JNEX-Core has been further developed, leading to even greater lower core loss in the high-frequency ranges.

|

Low Core Loss |

For high-frequencies in excess of 5 kHz, out shines even JNEX-Core for low core loss. |

|---|---|

|

Highly Workable |

Excellent workability for pressing, bending, stamping, etc. |

|

Non-oriented |

There is virtually no difference in the characteristics between the rolling direction (L-direction) and the transverse direction (C direction).Therefore, this can be used in a wide range of applications, from stationary machines to rolling machines. |

|

High-saturation magnetic flux density |

Has a high saturation magnetic flux density of 1.85 ~ 1.94 T Using this material in a reactor takes full advantage of the superior DC superimposition characteristics. |

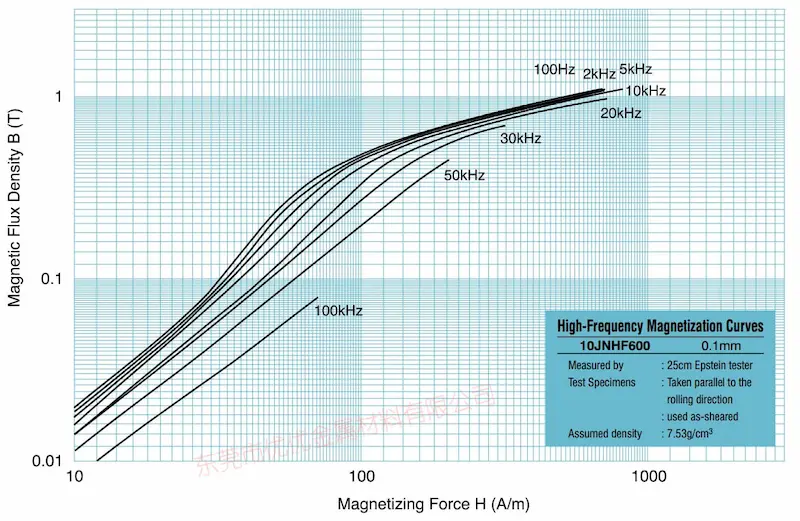

10JNHF600 High-Frequency Magnetization Curves

Custom Core

Stator and rotor

High-speed motors have been applied for varieties of applications, such as electric engines for aircraft, flywheel energy storage systems, highspeed spindles, gas compressors, turbo-molecular pumps, air blowers, turbochargers and micro-turbines, etc.

We have a wide range of specifications in stock, and we can customize motor cores of different sizes at any time. Using glue bonding + wire cutting method. Convenient small amount of proofing and batch stamping production. The processing is mature. For more details, please contact us.

Transformers

With the characteristic of low core loss at high-frequency, Super Core can be used for various types of transformers in a wide range of frequencies (x Hz to y kHz).

Super Core helps reduce heat generation in transformers and provides higher magnetic induction intensity than conventional silicon steel sheets, which can reduce the size of transformers. Other required components of transformer, such as the copper wire, can be downsized accordingly, resulting in overall cost reduction.

By taking the advantage of the low magnetostriction characteristics of JNEX-Core, the noise of transformers can be reduced dramatically.

Reactors

With the characteristics of high saturation magnetic flux density, low core loss at high-frequency, and high permeability, Super Core is ideal for applying to reactors with high-frequency current superimposition over a broad range of frequencies.

Super Core meets all high frequency wave regulations and power factor improvements. The demand is on the increase for its use in inverter output reactors, active filters, PWM converter reactors. It serves many market sectors, including consumer electronics, industrial renewable power generation, and automobile market.

Super Core meets diverse needs of customers. It can be formed into wound cores in various shapes, such as C-Cores and toroidal cores, as well as into lamination cores, glued block cores by cutting or pressing.

Core Shape

Glue bonding process, super core processing

Glued motor core, more compact assembly, improve the efficiency and performance of the motor, while also reducing noise and vibration.

Turbocharger high speed motor customized

Stator glue bonding + wire cutting method. Fast proofing, testing motor core performance superiority.

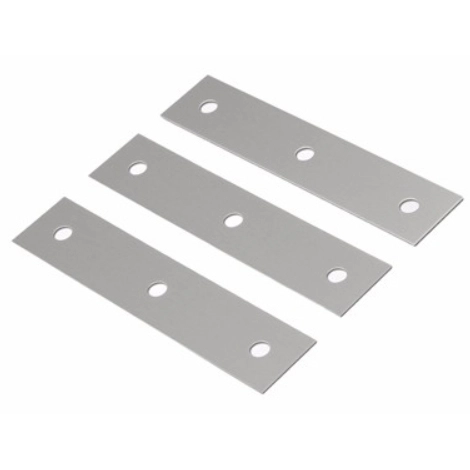

Block core with Round edge

A laminated core made in virtually the same shapeas a cut core, so that it is possible to use the samewashers and clamp bands.

Stacked Laminations

These cores are used mainly with medium- andlarge-sized transformers and reactors. The user stacks the strips and affixes them using bolts.

.webp)

Wound Core(C-Core & Toroidal Core)

After the steel is formed and annealed it is soaked in varnish and fixed, cut(if necessary). The sheet thickness is 0.1mm.Both standard & non-standard sizes C-Core are available.

Super Core Block Core

Block cores are for small and medium sized reactors and transformers, Effectivelv cost reduction for mass-producing.Standard lamination fixing method is adhesive fixation.